At Leadshine, we recognize that choosing the right servo drive is essential for precise and reliable motion control in industrial automation. A servo drive works in conjunction with an AC servo motor to regulate speed, position, and torque in various applications. Selecting the appropriate drive ensures system stability, accuracy, and efficiency, which are critical for CNC machinery, robotics, and automated production lines.

Motor Compatibility

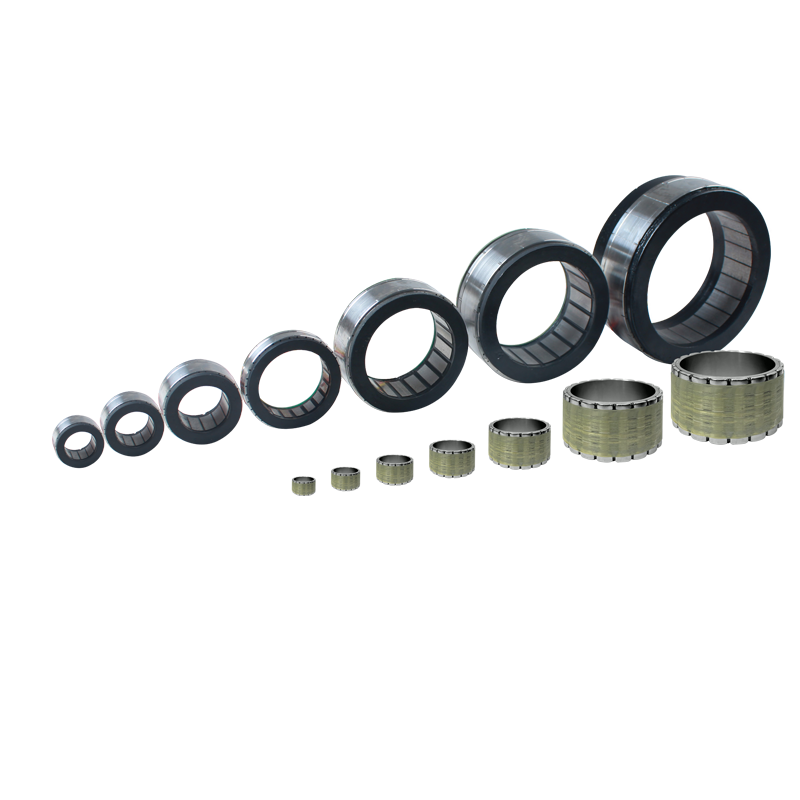

The first factor to consider is compatibility between the servo drive and the AC servo motor. Not all drives are suitable for every motor type, and mismatched systems can result in poor performance or even equipment damage. At Leadshine, we offer drives designed to integrate seamlessly with our range of AC servo motors, ensuring optimal torque control and responsiveness. Checking voltage, current, and power ratings is crucial to ensure the motor and drive work harmoniously.

Control Features

Modern servo drives provide a variety of control modes to meet different application requirements. Position control, speed control, and torque control are common options, and selecting a drive with the right features can improve system performance. Leadshine designs drives with flexible control modes and interfaces, allowing engineers to adjust settings for maximum precision and efficiency. Features such as programmable acceleration and deceleration, feedback loop tuning, and multi-axis synchronization can further enhance operation in complex machinery.

Feedback and Communication

Feedback mechanisms play a vital role in servo system performance. Encoders or resolvers attached to the AC servo motor provide real-time position and speed data to the servo drive, enabling accurate motion control. When selecting a drive, consider its ability to handle the feedback type and communication protocol used in your system. Leadshine's drives support multiple encoder types and offer reliable communication with common industrial protocols, helping maintain smooth and precise operation.

Performance and Reliability

Performance characteristics, including response speed, torque consistency, and thermal management, are critical when selecting a servo drive. Drives must handle continuous operation and varying load conditions without overheating or losing accuracy. At Leadshine, our drives are tested to meet rigorous performance standards and paired with AC servo motors designed for durability and consistent output, providing a reliable solution for demanding industrial environments.

Installation and Integration

Ease of installation and system integration is another important consideration. Drives should support straightforward wiring, configuration, and programming. Leadshine offers user-friendly setup procedures, clear documentation, and software tools to simplify integration with a wide range of automation systems. Reducing installation complexity saves time and helps engineers focus on optimizing machine performance rather than troubleshooting compatibility issues.

Conclusion

Selecting the right servo drive is crucial for achieving precise control and consistent performance with AC servo motors. At Leadshine, we emphasize compatibility, flexible control features, reliable feedback handling, robust performance, and straightforward integration. By evaluating these five key factors, engineers and system designers can make informed decisions, ensuring their motion systems operate efficiently and reliably. Our servo drives paired with AC servo motors provide a complete solution for a variety of industrial automation applications, helping businesses maintain accuracy and productivity.